The 2025 SCUPI Innovative Engineering Practicum was held successfully

Published on: August 2, 2025 | Views: 633

June 30–July 2, 2025, the 2025 SCUPI Innovative Engineering Practicum opened successfully, giving SCUPI students an immersive feast of learning that blended theoretical depth with hands-on breadth and launched them on an industry-discovery journey at the cutting edge.

Anchored in front-line technologies and leveraging the outstanding strengths of world-leading companies in innovation, the program is co-developed by SCUPI and its corporate partners to sharpen undergraduates’ practical creativity. Students experience industry charisma up close and unlock their own inventive potential.

Day 1 – June 30

Intel big-data expert Yang Runxing returned for the second consecutive year to teach ECE and CS majors. Dr. Minking Chyu, Dean of SCUPI opened the day and presented Yang with an official Instructor Certificate, thanking both him and Intel for their steadfast support of SCUPI education.

The two half-day sessions delivered a panoramic, step-by-step dissection of packaging-and-test process flows, capped with a forward-looking survey of advanced packaging technologies, painting a grand vista of industry evolution.

Crucially, real production data were woven into exploratory data-analysis exercises, letting students witness how analytical techniques drive real-world decisions and feel the power of theory-meets-practice. Last year, two SCUPI students who excelled in the course were selected to attend Intel Career Experiencing Week—living proof of the program’s value.

Since the SCUPI–Intel partnership began in November 2023, Intel has supplied end-to-end support: practice courses, capstone exhibitions, career coaching and more. This deep collaboration is a sturdy bridge to the forefront of industry, equipping students with rare opportunities and priceless insights to broaden horizons and map their futures.

Day 2 – July 1

Vice President of HR & Admin Huang Meng extended a warm welcome. Dr. Liu Di, Assistant Dean for Academic Affairs, presented an Instructor Certificate to Zhao Tianyuan, YIC’s market-product specialist.

Zhao’s lecture, “Overview of the IC & Advanced Packaging Industry”, traced history, current status and future trends—from basic concepts to core technologies—illustrated with vivid cases. Students asked questions enthusiastically, and Zhao answered patiently, creating a vibrant learning atmosphere.

The visit gave students a concrete, in-depth understanding of IC and advanced packaging, laying solid groundwork for subsequent study and career planning.

Day 3 – July 2

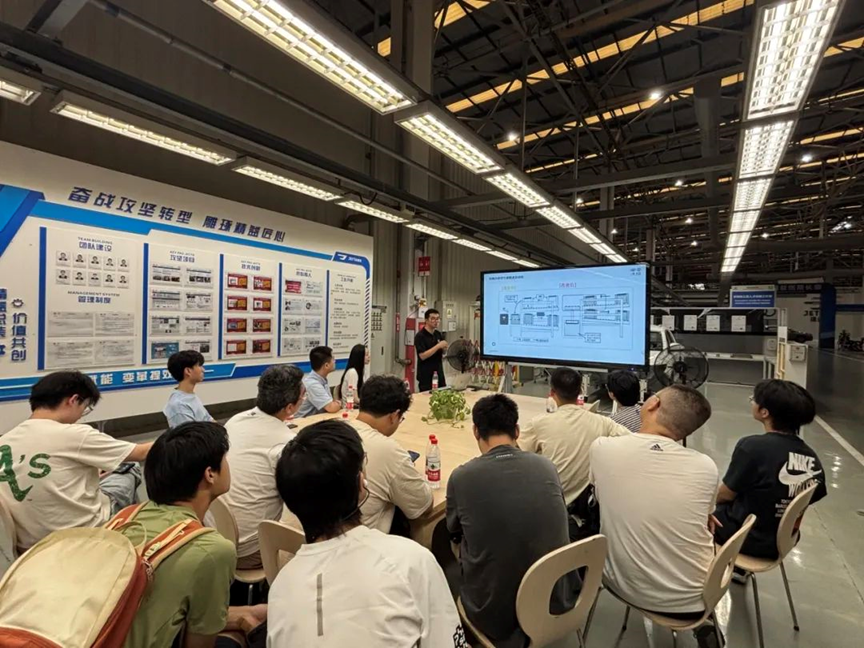

SCUPI joined FAW-Volkswagen Chengdu Branch for another edition of this Program. Dr. Liu Di, Assistant Dean for Academic Affairs, thanked FAW-Volkswagen for its trust and praised both teams’ dedication for giving students invaluable learning opportunities.

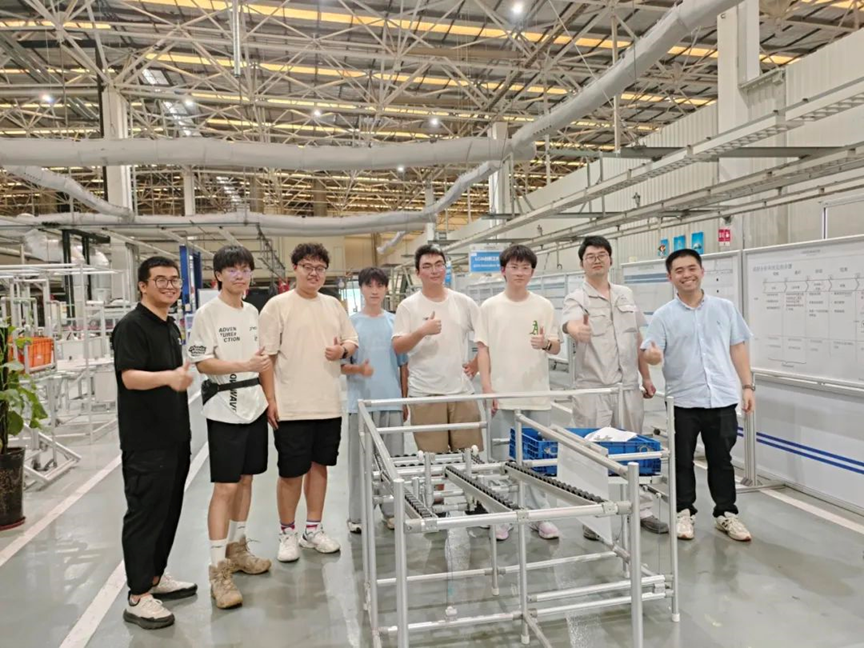

Modules led by specialists Huang Xuechuan (Production Management) and Luo Silong (Industrial Engineering) featured the E-Lane business-game simulation, low-cost automation training, and an introduction to core lean methods. Immersive learning and simulations let students grasp IE fundamentals and apply them to boost efficiency and cut costs.

The Truck Assembly-Line Simulation ran in two rounds focused on pull production and method-tool application. Students formed teams and experienced every link—planning, material supply, assembly—sensing the complexity and synergy of modern automotive manufacturing. A session on 5S on the shop floor and interdisciplinary discussions further broadened managerial mindsets, highlighting how disciplined workplace management and cross-functional communication drive operational excellence.

Tours of the body-weld and final-assembly shops opened students’ eyes: from parts to a finished vehicle, advanced welding robots and automated assembly lines under strict quality control revealed the artistry of automotive manufacturing and deepened their passion for engineering.

Expert Wang Yu gave ME majors a comprehensive lecture on Life-Cycle Impact Assessment (LCIA). In hands-on teamwork, students applied their new knowledge to an assembly challenge, reinforcing theory, honing practical skills, and sharpening problem-solving abilities.

Eight intensive hours of lectures, simulations, factory tours and expert talks blended multiple disciplines and front-line technologies. The program sparked initiative, nurtured innovative thinking and teamwork, and built a solid foundation for students’ future engineering careers —while offering SCUPI valuable experience for further educational reform.