SCUPI Introduces New Lab Projects and Facilites to Enhance Students’ Practical Competence

Published on: December 22, 2025 | Views: 240

By introducing new projects and facilities, the SCUPI Lab teaching team has achieved a series of significant results in courses such as Materials Science, Mechanical Measurement, and Mechatronic Control. These outcomes have contributed to the comprehensive enhancement of students’ innovative competencies and practical skills.

Step into the Micro-Nano World of Materials – Nanoindentation Experiment Officially Launched

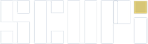

Utilizing the Institute’s nanoindenter, Professor Yingjie Wu has launched an “Experience High-value Instruments” project for Materials Science and Engineering (MSE) students. Titled “Nanoindentation Characterization of Functionally Graded Materials and Microscale Analysis of Mechanical Properties,” the project provides hands-on training in nanoindentation and in situ imaging experiments using materials such as 316L/In718. Students learn to measure hardness, elastic modulus, and time-dependent deformation at the micro/nano scale. The program covers theoretical principles, instrument operation, data processing, and visualization—guiding students from simply experiencing advanced instruments to confidently using them.

Students operating the nanoindentation equipment

Demo of experimental data

Experience Mechatronic Intelligent Control – Rotary Inverted Pendulum Control Experiment Implemented

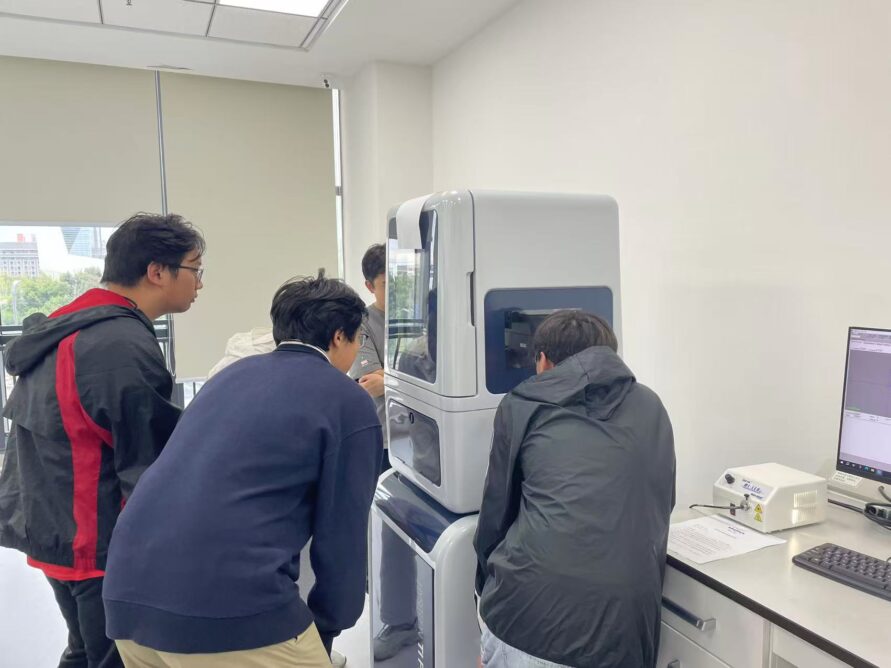

In experimental courses for Mechanical Engineering students, Professor Qi Lu and laboratory engineer Wenwen Hu developed a comprehensive project titled “Inverted Pendulum System Identification.” Centered on engineering system modeling, the project forms a complete workflow from theoretical derivation to experimental verification. Students collect input-output data from physical inverted pendulum and DC servo systems, use the least squares method for parameter identification, and compare the results with theoretical models derived from physical principles. Through systematic experimental processes and code practice, students not only master basic tools of modern control systems but also gain transformative training from mathematical modeling to engineering implementation.

Inverted pendulum experimental platform

Simulation and experimental data

Upgraded Additive Manufacturing System – New 3D Printers and Tool Cabinets in Service

To strengthen teaching and research support and enhance the user experience of processing equipment, the lab team has deployed Bambu Lab 3D printers and tool cabinets in the basement, building a more efficient hardware platform.

The new dual-nozzle Bambu printers enable multi-color and multi-material printing with high precision and compatibility with materials such as PLA, ABS, and TPU, addressing needs ranging from coursework to advanced research. In addition, dedicated tool cabinets have been installed in the machining area, facilitating on-demand use for students.

Bambu Lab 3D printers

Tool cabinets

Looking ahead, through the collaborative efforts of the faculty and laboratory team, SCUPI will continue advancing a fundamental transformation in practical teaching—from skill training to cultivating innovative capacity—ultimately establishing a leading center for interdisciplinary, high-level, and sustainable engineering practice education.